DIY STANDARD SHAPE SHADE SAIL

INSTALLATION INSTRUCTIONS“How to Install a Sail in 8 Easy Steps”

-

Put the seams and hems on the top. This’ll stop mould build-up and make it easier to dry.

-

Attach the direct fix points first.

-

Open, lube, and hang the turnbuckles off the posts. Use some graphite anti-seize, vaseline, sewing machine oil, or axle grease. It’s important to lube the turnbuckles because SST is brittle and will seize if you’re not careful.

-

Make sure the right-turning end of the turnbuckle is on the post, not the sail. The left-hand end goes on the sail.

-

Lube the corner fitting (D ring) cable groove. This’ll stop the cable from sticking as you tighten the sail. A spray can of lubricant with a nozzle is the easiest way to do this.

-

Fix the sail to each fixing point using the starter cord (rope) attached. Loop it over the post, back to the sail 2 or 3 times to get some leverage.

-

Get the sail into a position you’re happy with, then measure each gap. If necessary, order some turnbuckles and/or cable trace from our hardware page.

-

Attach and tighten the turnbuckles sequentially until you have enough tension on the sail. The fabric should be pulled tight and the cable should be pulled tight. If your fixing points are strong, you can put plenty of tension on the sail. Use your judgement. The tighter the sail, the better it will handle storms.

DIY STANDARD SHAPE SHADE SAIL INSTALLATION GUIDE

©DIY Shade Sails Australia

Your new Standard Shape DIY Shade Sail may require Stainless Steel Hardware, such as Turnbuckles, Cable Trace and D Shackles, all available from our Hardware page.

Fittings are not included with any Standard Shape Shade Sail purchase.

It is quite possible to get a good result with our “Standard Size” shade sails.

Remember, the sail will stretch around 10%.

We have calculated the exact length of the SST cable which is now swaged off in the perimeter of your shade Sail. You must stretch the sail out using turnbuckles, or, UV resistant cord, to fully tighten the SST cable.

If you get this right, you will have a well tensioned Shade Sail which will look as though it has been installed by professional Shade Sail technicians.

The first step is to lay the sail out on the ground where you plan to install your fixing points.

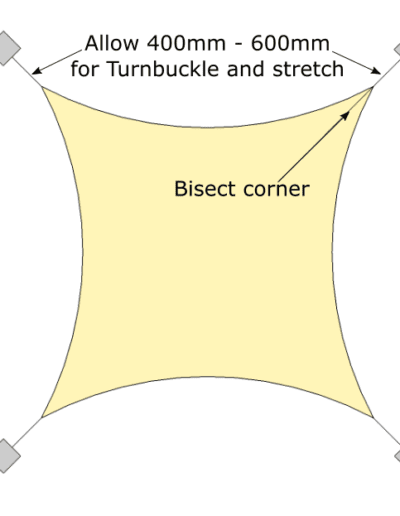

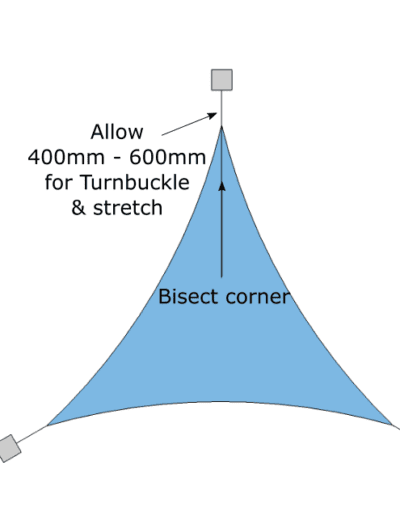

Allow at least 400mm – 600mm outside the edge of the sail for each corner.

It is easy to fill in the gap with turnbuckles and /or a cable trace.

If you don’t leave enough room, that is much harder to overcome.

Best to leave more space not less.

Using the rope attached, fit the sail to the fixing points.

Pull the ropes as tight as possible until you are happy with the position.

Take a note of each gap and, if necessary, go to the Hardware page and order cable trace and turnbuckles as needed.

You are trying to bisect the corner with your fitting attachment.

The diagrams on this page should illustrate to you how to achieve this.

If you get this right, you will end up with a professional appearance, for a fraction of the price of paying the Shade Sail Companies to supply and install.

Of course, you are constrained by the fact that you are working with a specific sized sail so, you need to conform your posts, fixing points etc. exactly to the sail.

If you are installing posts, we recommend a minimum of 65mm x 65mm x 3mm.

Better to use 75mm x 75mm x 3mm for higher sails up to 2.8 – 3.3m above ground and, for higher posts it is best to go to 100mm x 100mm x 4mm.

This is the post size the professionals mostly use and is well worth the extra cost.

Footings should be 1000mm x 350mm, the concrete at least 20MPA strength, better to overdo the strength as inevitably, a storm will test out your work.

Square your post from each side but lean the post back around 5 – 7 degrees, which is industry standard.

We can supply the 316 grade Stainless Steel eye-nut assembly for fitting off the post as well as the caps to suit whichever post you use. (check out the hardware page) As a rule we use 10mm eyenuts. 1 hole drilled 50mm from the top of the post, bolt on the fitting then attach the cap and you have exactly the method used by the shade sail pros.

Whether fixing to masonry, brick-work, timber or another material, there is a variety of fittings to suit your purpose.

We have always found individual situations can require a practical solution.

We have been constantly amazed, over the years at the clever solutions dreamed up by our DIY customers.

You too can build a unique and attractive shade sail installation for a very competitive price, cutting out much of the cost and with the satisfaction of building it yourself.

After your purchase we will supply a free consultation to further assist you in achieving a fantastic result.

NB: Shade Cloth can tear if it catches on, eg. a box gutter corner etc. All care must be taken

TIGHTENING THE TURNBUCKLE ON A STANDARD SAIL